Introduction to IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

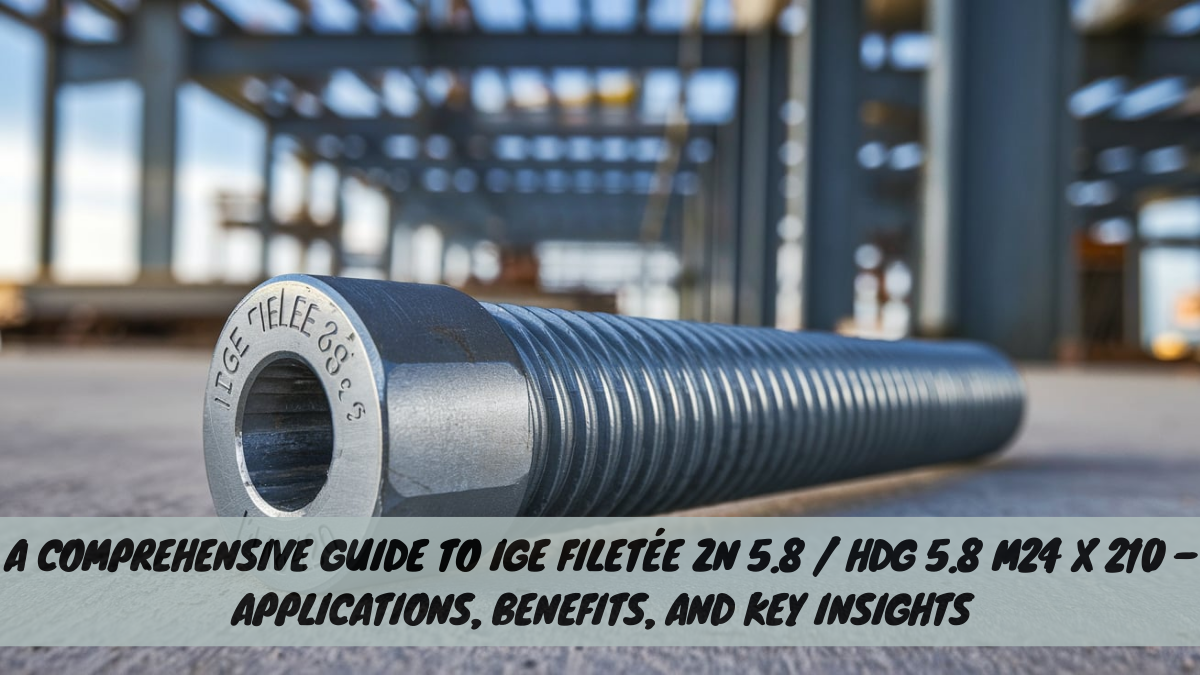

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a specialized threaded rod used in various heavy-duty applications, including structural steel construction, machinery, and large-scale equipment. It’s part of a broader category of fasteners that offer durability, corrosion resistance, and significant load-bearing capacity. For anyone involved in construction, engineering, or industrial applications, understanding the specifications and benefits of this rod is critical to selecting the right material for your projects.

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is a high-strength threaded rod widely used in construction, machinery, and structural applications for its durability and corrosion resistance.

In this article, we’ll break down the properties of this threaded rod, explain why it’s a trusted solution, and provide insights into its common uses. Whether you’re a construction professional or just looking to learn more, this comprehensive guide will cover everything you need to know about the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210.

What Does “IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210” Mean?

To better understand the term, let’s break it down into its components:

- IGE Filetée: Refers to a threaded rod or bolt, which is commonly used to fasten or connect components together.

- Zn: Stands for zinc, indicating that the rod is zinc-coated, offering enhanced corrosion resistance. Zinc-plated materials are popular in outdoor and heavy-duty applications due to their ability to resist rust.

- 5.8: This number refers to the strength class of the steel used. Class 5.8 is commonly used in construction as it offers a balance between strength and ductility. It’s strong enough to bear loads while being ductile enough to deform slightly without breaking.

- HDG (Hot Dip Galvanized): This refers to the coating method where the rod is dipped in molten zinc, ensuring a thicker zinc layer for long-term corrosion protection.

- M24: Indicates the diameter of the rod. M24 means the rod has a 24mm diameter, which makes it suitable for heavy-duty applications.

- 210: The length of the rod in millimeters (210mm), offering flexibility for various mounting and fastening applications.

Key Features and Benefits of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 stands out for several reasons, which make it a top choice for construction and industrial uses.

1. Corrosion Resistance

The zinc coating ensures that the rod is highly resistant to corrosion, making it ideal for outdoor applications where exposure to moisture and other elements could lead to rusting. The HDG (hot-dip galvanization) process guarantees a thicker layer of zinc protection compared to traditional zinc plating.

2. High Strength (5.8 Class)

With a 5.8 strength rating, this rod offers a good balance between tensile strength and ductility. This means that while the rod can handle significant loads, it is also able to deform slightly without snapping under extreme conditions, making it a safer option in dynamic environments.

3. Suitable for Heavy-Duty Applications

With a 24mm diameter (M24), this threaded rod is large enough to be used in heavy-duty applications. Whether it’s used in steel frameworks, machinery assembly, or equipment anchoring, the rod can handle substantial loads without buckling.

4. Precision Engineering

IGE Filetée rods are manufactured with precision threading to ensure seamless compatibility with nuts and other fastening components. The M24 x 210 size makes it ideal for structural applications where exact fits are crucial for stability.

Common Uses of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

This threaded rod has a wide range of applications, especially in industries where strength, durability, and corrosion resistance are essential. Below are some common uses:

1. Construction and Structural Engineering

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is frequently used in steel frame construction. The rod helps secure beams, columns, and other structural components together, providing integrity and support to the entire structure. Its corrosion resistance makes it especially valuable in outdoor environments.

2. Machinery and Equipment Assembly

In industries where large machinery needs to be assembled or repaired, the M24 threaded rod is used to fasten heavy components. This could include industrial machines, agricultural equipment, or automotive parts where strength and stability are critical.

3. Bridges and Heavy Infrastructure

In infrastructure projects like bridges, the threaded rod is used for securing parts of the support structure. Due to its high strength and resistance to environmental conditions, it plays a critical role in load-bearing components that require longevity.

4. Industrial Fastening Systems

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 rod is also commonly used in various industrial settings to secure systems such as conveyor belts, assembly lines, or piping systems. Its ability to withstand heavy use and stress over long periods makes it highly suitable for industrial uses.

How is the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 Manufactured?

The manufacturing process of the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 involves several key steps:

1. Raw Material Selection

High-quality steel is selected for the rod. In this case, steel of class 5.8, which offers the right balance between strength and ductility.

2. Thread Cutting

Once the steel rod is shaped, threads are cut into the rod with high precision. The threading is critical for ensuring compatibility with nuts and washers that will be used for fastening.

3. Hot-Dip Galvanization

The rod undergoes hot-dip galvanization, where it is submerged in molten zinc. This process forms a robust corrosion-resistant layer, which is essential for applications exposed to weather, moisture, or chemicals.

4. Quality Control

Finally, the rods are tested to ensure they meet the required standards for load-bearing capacity, thread precision, and zinc coating thickness. Only rods that meet stringent criteria are approved for industrial use.

Key Factors to Consider When Choosing a Threaded Rod

When selecting a threaded rod like the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210, there are several factors you should consider:

- Corrosion Resistance: If the rod will be used outdoors or in a corrosive environment, hot-dip galvanized (HDG) options are preferred.

- Load Requirements: Ensure that the tensile strength matches the needs of your project. For structural applications, a class 5.8 rod provides adequate strength.

- Compatibility: Consider the threading and diameter to ensure compatibility with other components such as nuts, bolts, and washers.

- Length: Ensure the rod is the right length (in this case, 210mm) for your specific application.

Advantages of Zinc-Coated vs. Hot-Dip Galvanized Threaded Rods

One important comparison when discussing the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is between the different coating methods, zinc plating and hot-dip galvanizing. Here are the main differences:

Zinc Plating (Zn)

- Thinner coating than hot-dip galvanizing.

- Best suited for indoor or dry applications where corrosion risk is lower.

- Typically used for smaller, lighter-duty applications.

Hot-Dip Galvanizing (HDG)

- Thicker zinc layer, providing superior corrosion resistance.

- Ideal for outdoor environments, especially where moisture is present.

- Commonly used in heavy-duty applications such as infrastructure projects, machinery, and industrial fastening.

Installation and Maintenance of IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210

1. Installation Tips

- Clean Threads: Ensure that the threads are free from debris and contaminants. This will ensure proper engagement with the nuts and washers and prevent any potential stripping or damage.

- Use Compatible Nuts and Washers: Always select nuts and washers that match the specifications of the M24 rod. Using incompatible components can lead to failure in load-bearing applications.

- Torque Specifications: Follow the manufacturer’s recommended torque specifications when tightening the rod. Proper torque ensures that the connection is secure without overstressing the rod or damaging the threads.

- Check Alignment: Make sure that the rod is aligned correctly with the components it’s fastening. Misalignment can lead to uneven stress distribution, which may compromise the integrity of the installation.

2. Maintenance Recommendations

- Regular Inspections: Periodically inspect the threaded rod for signs of corrosion or wear, especially if used in harsh environments. Look for any physical damage or loosening of connections.

- Environmental Considerations: If the rod is exposed to saltwater or chemicals, consider additional protective measures, such as applying a protective coating or sealant to prolong its lifespan.

- Tightening Checks: Recheck the torque settings periodically, particularly in dynamic applications where vibrations may loosen fasteners over time. This is crucial for maintaining safety and structural integrity.

- Replace Damaged Rods: If any signs of damage or corrosion are observed, replace the rod promptly to avoid failure in the fastening system.

Conclusion

The IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 is an essential component in various construction, industrial, and machinery applications, offering superior strength, corrosion resistance, and reliability. Its robust construction and high-quality manufacturing processes make it a preferred choice for professionals seeking durable fastening solutions.

Understanding its features, applications, and maintenance requirements can significantly enhance project outcomes, ensuring structural integrity and safety in demanding environments. By choosing the right threaded rod and adhering to best practices for installation and maintenance, engineers and construction professionals can achieve optimal performance in their projects.

FAQs

1. What is the main advantage of using IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 threaded rods?

The primary advantage is its high strength and excellent corrosion resistance, making it ideal for heavy-duty applications in outdoor and industrial settings.

2. How does hot-dip galvanization differ from zinc plating?

Hot-dip galvanization involves dipping the rod in molten zinc, creating a thicker, more protective coating compared to zinc plating, which applies a thinner layer suitable for lighter-duty applications.

3. In what industries is the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 commonly used?

It is commonly used in construction, machinery assembly, infrastructure projects (like bridges), and various industrial fastening systems.

4. What maintenance practices should be followed for the IGE Filetée Zn 5.8?

Regular inspections, checking torque specifications, and monitoring for corrosion or wear are essential to maintain the rod’s integrity and performance.

5. Can the IGE Filetée Zn 5.8 / HDG 5.8 M24 x 210 be used in coastal areas?

Yes, it is suitable for coastal applications due to its hot-dip galvanized coating, which provides superior corrosion resistance against moisture and saline environments.